Ever found yourself rummaging through your desk drawer, wondering which staple size you need for that stack of papers? You’re not alone. The humble staple that tiny metal fastener we often take for granted comes in a surprising variety of sizes, each designed for specific purposes.

From the miniature staples that barely pierce a few sheets to the industrial-strength fasteners that bind thick booklets, these little workhorses have been keeping our papers together since the late 19th century.

While they might seem insignificant, choosing the right staple size can mean the difference between a neat, professional document and a frustrating mess of bent metal and torn paper.

Let’s dive into the world of staple sizes and discover how these small but mighty fasteners measure up against other common objects in our daily lives.

How Long Are Staples?

Standard staples typically range from 1/4 inch (6mm) to 3/4 inch (19mm) in length, with the most common office staple measuring about 1/4 inch to 3/8 inch (6-10mm).

This seemingly tiny measurement packs a mighty punch in the world of paper fastening! To put this in perspective, a standard staple is roughly the width of your pinky fingernail or the diameter of a pencil eraser.

Despite their diminutive size, these metal wonders can hold together anything from a few sheets of paper to substantial documents.

Standard Office Staples (26/6)

The staple you’ll find in most office staplers goes by the technical name “26/6” a designation that might seem mysterious until you break it down. The “26” refers to the wire gauge (thickness), while the “6” indicates the leg length in millimeters.

These ubiquitous fasteners measure approximately 1/4 inch (6mm) in length and can typically handle between 2-20 sheets of standard paper. Their crown (the flat top part) spans about 1/2 inch (12.7mm), creating that familiar dual-puncture pattern we all recognize.

What makes this size so popular isn’t just tradition but ergonomic practicality. The 26/6 staple hits the sweet spot of being small enough to not waste metal yet sturdy enough to secure everyday documents. Next time you click down on your desktop stapler, appreciate that its dimensions have been refined through decades of office evolution.

Did you know? Americans use an estimated 25-35 billion staples annually enough to circle the Earth several times if laid end to end. The standard office staple has remained virtually unchanged in design since the early 1900s, proving that sometimes, the simplest solutions are the most enduring.

Heavy-Duty Staples (23/8 to 23/15)

When regular staples just won’t cut it, heavy-duty staples step in to save the day. These beefier fasteners, commonly designated as 23/8, 23/10, 23/13, or 23/15, range from approximately 5/16 inch (8mm) to nearly 5/8 inch (15mm) in length.

The increased leg length allows these staples to penetrate deeper, securing thicker stacks of paper with ease. A 23/8 staple can typically handle 30-50 sheets, while the mighty 23/15 can tackle up to 100 sheets or more. The wire gauge (indicated by “23”) is also thicker than standard staples, providing additional strength and durability.

Heavy-duty staples are indispensable in busy offices, print shops, and publishing houses where substantial documents need binding. Marketing departments particularly rely on these staples when creating product catalogs and presentation materials that need to withstand frequent handling.

Fascinating fact: The development of heavy-duty staples represented a crucial innovation in office technology, dramatically reducing the time needed to assemble large documents compared to older binding methods like stitching or gluing. Before their invention, binding thick documents often required specialized equipment or outsourcing to professional bookbinders.

Miniature Staples (26/4)

At the smaller end of the spectrum, we find miniature staples like the 26/4, measuring just over 5/32 inch (4mm) in leg length. These tiny fasteners serve specialized purposes where discretion and minimal paper penetration are priorities.

Commonly used in light-duty staplers and mini staplers designed for portability, these diminutive staples create less noticeable punctures and are perfect for temporarily securing just a few sheets of paper. They’re especially useful for documents that will later be scanned or filed, as they leave smaller holes when removed.

Miniature staples have found a niche in craft projects, bookbinding, and even certain medical applications where precision matters. Their unobtrusive profile makes them ideal for delicate papers and situations where aesthetics count.

Curious tidbit: Mini staples were originally designed for attaching price tags to clothing and other retail items before the widespread adoption of plastic fasteners. Today, their applications have expanded far beyond retail, though they remain a staple (pun intended) in the fashion industry for attaching hang tags.

Booklet Staples (24/6 to 24/10)

When it comes to creating professional-looking booklets and brochures, booklet staples take center stage. These specialized fasteners, typically designated as 24/6, 24/8, or 24/10, range from approximately 1/4 inch (6mm) to 3/8 inch (10mm) in leg length.

The “24” gauge wire strikes a balance between flexibility and strength, allowing the staple to bend easily during the binding process while still maintaining structural integrity. The longer legs accommodate the fold in saddle-stitched publications, penetrating through multiple sheets before being clinched on the inside.

Professional printers and publishers rely on these staples for magazines, event programs, and marketing materials. Their optimized dimensions ensure that the finished product lies flat when opened while keeping all pages securely bound.

Intriguing insight: The term “saddle-stitching” comes from the traditional binding method where folded sheets were placed over a saddle-like device before being stitched together. Modern staplers have mechanized this process, but the distinctive look of center-stapled publications remains largely unchanged from their handcrafted ancestors.

Industrial Staples (Various Sizes)

Beyond the office and into construction and manufacturing realms, industrial staples take on dimensions that dwarf their desktop counterparts. These heavy-duty fasteners can range from 3/8 inch (10mm) to a substantial 2 inches (50mm) or more in length.

Used in upholstery, roofing, insulation installation, and packaging, industrial staples feature thicker wire gauges and specialized shapes designed for specific applications. Their crown width and leg length vary significantly based on the materials they’re designed to join from soft fabrics to hard woods and even concrete backing.

Construction-grade staples often include adhesive coatings or special finishes to enhance holding power and resist corrosion. The sizing conventions for these staples typically follow a different nomenclature than office varieties, often specified by actual measurements rather than the gauge/length format.

Remarkable revelation: Some industrial staple guns can drive staples with enough force to penetrate hardwoods and even thin metal sheets. The largest industrial staples can exert holding forces measured in hundreds of pounds per square inch a far cry from the gentle grip of their office cousins.

Surgical Staples

In a fascinating crossover between office supplies and medical technology, surgical staples represent perhaps the most specialized application of the staple concept. These medical devices typically measure between 3/16 inch (4.8mm) and 1/4 inch (6.4mm) in width, with varying leg lengths depending on the tissue thickness they’re designed to join.

Unlike standard metal staples, surgical varieties are crafted from specialized biocompatible materials like titanium, stainless steel, or even absorbable polymers that dissolve as the body heals. Their dimensions are precisely calibrated to provide optimal wound closure while minimizing tissue trauma.

Surgical stapling has revolutionized many medical procedures, reducing operation times and improving healing outcomes. The technology has evolved from simple skin closure applications to sophisticated internal stapling devices used in thoracic and abdominal surgeries.

Medical marvel: Surgical stapling techniques can reduce operation time by up to 75% compared to traditional suturing methods in certain procedures.

The precision engineering of these specialized staples allows surgeons to create consistent, strong closures even in challenging anatomical locations.

See Also: Thank You Card Sizes (Standard & Other Sizes)

Real-World Applications and Measurement Tips

Visualizing Staple Sizes in Everyday Life

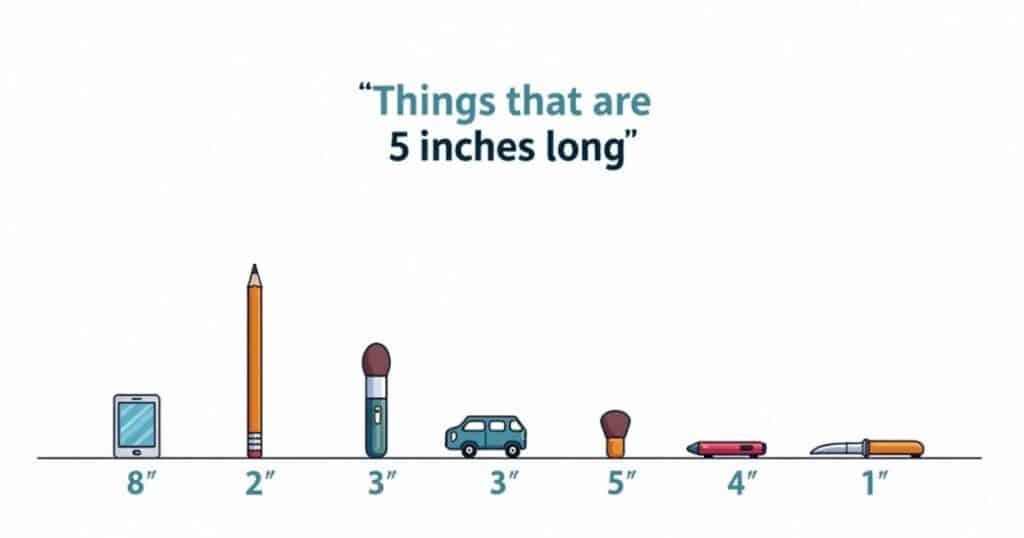

Understanding staple sizes becomes more intuitive when we compare them to objects we encounter daily:

- A standard 26/6 staple leg length (1/4 inch) is approximately the thickness of two quarters stacked together

- The crown width of a typical staple (1/2 inch) closely matches the width of a standard wooden pencil

- A heavy-duty 23/15 staple (5/8 inch) approaches the diameter of a standard drinking straw

- The smallest miniature staples (1/8 inch) are roughly the thickness of a credit card

These visual references can help when you’re trying to determine which staple size you need without having a ruler handy.

Measuring Without Tools

When you’re in a pinch and need to estimate staple sizes without a ruler, try these practical approaches:

- Use currency: A U.S. quarter is approximately 1 inch in diameter, making it a convenient measuring tool for staple lengths.

- Paper thickness: A standard sheet of 20 lb copy paper is about 0.004 inches thick. Count how many sheets your stapler can handle to estimate the appropriate staple length (approximately 1mm of staple length for every 5 sheets).

- Check your cell phone: Many smartphones are close to 3 inches wide, giving you a built-in measuring reference.

- Employ your hand: The width of your thumb at the knuckle is roughly 1 inch for most adults, making it a portable measuring tool for estimating staple crown widths.

- Credit card edge: The short edge of a standard credit card measures approximately 2.125 inches a useful reference when selecting staples for thicker documents.

Practical Tips for Choosing the Right Staple Size

To avoid jammed staplers and improperly secured documents:

- For everyday office use with 2-20 sheets, standard 26/6 staples work perfectly

- When binding 20-50 sheets, upgrade to 23/8 or 23/10 heavy-duty staples

- For documents exceeding 50 sheets, choose 23/13 or 23/15 staples and ensure your stapler is rated for heavy-duty use

- When creating professional booklets, select 24/6 or 24/8 staples specifically designed for saddle-stitching

- Consider the removal process larger staples create bigger holes, which might be undesirable for documents that will be unstapled later

See Also: Samsonite Suitcase Sizes: A Complete Guide

The Evolution of Staple Sizes

The history of staple sizing reflects broader technological and workplace trends. The earliest modern staplers, developed in the late 19th century, used larger, custom-made fasteners that bear little resemblance to today’s standardized sizes.

As office work expanded during the 20th century, manufacturers began standardizing staple dimensions to ensure compatibility across devices.

The emergence of the 26/6 as the dominant office staple represents a convergence of factors: adequate strength, minimal material usage, and compatibility with compact desk staplers.

Recent decades have seen further specialization, with sizes optimized for specific applications from booklet binding to heavy construction. The development of cordless electric staplers has also influenced staple design, with dimensions adjusted to accommodate battery-powered mechanisms.

Industry Standards and Global Variations

Interestingly, staple size conventions vary somewhat across global markets. European manufacturers often use slightly different designation systems than their American counterparts, though the physical dimensions remain comparable. For instance, what Americans call a 26/6 staple might be labeled as No.10 in some European markets.

ISO standards have helped create some uniformity, particularly for industrial applications where precision matters. However, legacy sizing systems persist in many markets, creating occasional compatibility challenges for global businesses.

Conclusion

From securing a few sheets of notes to binding booklets or even closing surgical wounds, these tiny metal fasteners demonstrate how something seemingly insignificant can have outsized importance. The next time you reach for your stapler, you might appreciate the precision engineering behind that small piece of bent wire.

Understanding staple sizes helps us make better choices in our daily work whether that’s selecting the right fastener for an important presentation or ensuring our construction project uses appropriate materials. It’s a perfect example of how standardized measurements bring order and efficiency to our world.

Looking around your home or office, you might be surprised how many stapled items you can find from magazines and catalogs to furniture upholstery and packaging. Each represents a careful choice of staple size and type, optimized for its specific purpose.

So the next time you hear that satisfying “chunk” of your stapler binding papers together, remember there’s a whole world of precision engineering behind that humble office supply.

Read more knowledgeable blogs on Measure Take.