Ever found yourself puzzling over how much cargo you can fit in a semi-truck? Or maybe you’re planning a move and wondering which truck size will accommodate your belongings?

Understanding trucking space dimensions isn’t just for logistics professionals it’s practical knowledge that can save you time, money, and headaches whether you’re shipping products, moving homes, or managing a supply chain.

From the compact delivery vans that navigate city streets to the massive 53-foot trailers cruising down interstates, trucking spaces come in a fascinating variety of sizes, each designed for specific purposes. Let’s dive into this world of wheels and cargo capacity that keeps our economy rolling.

How Big Are Trucking Spaces?

Trucking spaces range dramatically from small box trucks measuring 10-12 feet in length to massive semi-trailers stretching up to 53 feet. These dimensions aren’t arbitrary; they’ve evolved to meet specific transportation needs while complying with road regulations.

When you see an 18-wheeler on the highway, you’re looking at approximately 48-53 feet of cargo space that can hold 26 standard pallets or up to 45,000 pounds of freight, depending on the configuration.

Visualizing these spaces can be challenging. Think about it this way: a standard 53-foot trailer could fit around three average-sized cars parked end-to-end, or roughly 13 king-sized mattresses stacked flat.

This practical understanding of truck dimensions helps businesses optimize shipping costs and individuals choose the right moving vehicle.

Box Trucks and Straight Trucks

1. 10-12 Foot Box Trucks

The compact warriors of the trucking world, these vehicles are perfect for navigating tight urban environments and handling smaller deliveries or moves.

These trucks typically offer 380-450 cubic feet of cargo space and can carry loads weighing 3,000-4,000 pounds. They’re the go-to choice for small apartment moves, typically accommodating the contents of a studio or one-bedroom apartment.

What makes these trucks particularly valuable is their accessibility they don’t require commercial driver’s licenses to operate, making them popular choices for DIY movers and small businesses making local deliveries.

Did you know that despite their smaller size, these trucks often consume more fuel per ton-mile than their larger counterparts? This counterintuitive fact stems from their less aerodynamic design and older technology compared to the constantly updated long-haul fleet.

2. 16-Foot Box Trucks

The sweet spot for many small businesses and mid-sized moves, 16-foot box trucks strike a balance between capacity and maneuverability.

With approximately 800 cubic feet of cargo space, these vehicles can typically handle 4,300-5,700 pounds of freight or the contents of a two-bedroom apartment. Their height usually reaches about 7’2″ to 8’2″, providing enough clearance for taller furniture pieces like wardrobes and china cabinets.

In the business world, these trucks serve as workhorses for appliance deliveries, catering services, and local product distribution. Their loading height sits lower than semi-trailers, making them easier to load and unload without specialized equipment.

The logistics industry values these trucks particularly for their “last mile” delivery capabilities bridging the gap between large distribution centers and final destinations where bigger trucks can’t easily access.

3. 24-26 Foot Box Trucks

These larger straight trucks represent the upper limit of what’s typically available for consumer rental and small business ownership without venturing into commercial trucking territory.

Boasting 1,400-1,600 cubic feet of cargo volume and weight capacities of 10,000-26,000 pounds, these trucks can handle the contents of a three to four-bedroom house or substantial commercial deliveries. Their interior dimensions typically measure around 24-26′ long × 8’5″ wide × A7’8″ high.

Many of these trucks feature amenities that make loading easier, including pull-out ramps or hydraulic lift gates that can raise heavy items from ground level to the truck bed.

A fascinating industry shift has been occurring with these larger box trucks they’re increasingly equipped with telematics systems that track fuel efficiency, driver behavior, and maintenance needs.

For fleet operators, this technology can reduce operating costs by 5-15% through optimized routes and driving habits.

Semi-Trailers

1. 28-Foot “Pup” Trailers

These shorter semi-trailers earned their nickname “pups” because they’re often used in tandem two connected to a single tractor in what’s called a “doubles” configuration.

A standard 28-foot trailer provides roughly 2,000 cubic feet of cargo space and can handle 22,500 pounds of freight. In LTL (Less Than Truckload) shipping, these trailers excel at efficient transport of multiple smaller shipments.

Their standardized dimensions allow for optimized loading and unloading at terminals designed specifically for quick trailer swapping.

In the hub-and-spoke distribution model that dominates much of American freight movement, pups play a crucial role in regional distribution.

Here’s something you might not know: doubles configurations with two 28-foot trailers actually have better fuel efficiency per ton-mile than single 53-foot trailers in many scenarios, despite pulling more total weight.

This efficiency comes from the ability to drop and hook trailers at different locations without unloading and reloading freight.

See Also: Sticky Note Dimensions: The Perfect Size for Your Thoughts

2. 40-Foot Containers/Trailers

The workhorses of international shipping, 40-foot containers have standardized global commerce and can be seamlessly transferred between ships, trains, and trucks.

These containers offer approximately 2,400 cubic feet of space and can handle weight capacities of 44,000-67,200 pounds, depending on the specific design and regulations. Their standardized external dimensions (40′ × 8′ × 8’6″) have literally shaped global supply chains.

The genius of these containers lies in their intermodal compatibility they can be lifted directly from ships onto railcars or chassis for trucking without unloading the contents. This innovation has dramatically reduced shipping costs and handling time.

The shipping industry measures cargo capacity in TEUs (Twenty-foot Equivalent Units), with a 40-foot container equaling 2 TEUs. The largest container ships can now carry over 24,000 TEUs a staggering amount of cargo that would require thousands of trucks to transport overland.

3. 48-Foot Trailers

Once the standard in long-haul trucking, 48-foot trailers remain common on American highways despite the industry shift toward 53-foot trailers.

With approximately 3,500 cubic feet of cargo space and weight capacities up to 45,000 pounds, these trailers can accommodate 24 standard pallets when loaded efficiently. Their interior dimensions typically measure around 47’6″ × 8’2″ × 9’6″.

These trailers strike a balance between capacity and maneuverability that makes them ideal for deliveries to locations with tight turning radiuses or limited dock space.

In the Northeast United States, where older infrastructure and tighter urban environments create challenges for larger trucks, 48-foot trailers remain particularly common.

In a fascinating historical note, the standardization of trailers to 48 feet in the 1980s represented a major shift in American trucking efficiency, allowing nearly 30% more cargo per trip compared to previous standards a change that significantly reduced transportation costs across the economy.

4. 53-Foot Trailers

The current standard for long-haul trucking in North America, these massive trailers represent the maximum legal length in most states without special permits.

Offering approximately 4,000 cubic feet of space and similar weight capacities to 48-foot trailers, these giants can accommodate 26 standard pallets. Their interior dimensions typically measure around 52’6″ × 8’2″ × 9’6″, providing substantial cubic capacity for bulky but lightweight goods.

The additional five feet of length compared to 48-foot trailers might seem small, but it represents an 8% increase in cubic capacity a significant efficiency improvement when multiplied across millions of shipments annually.

For lightweight goods that “cube out” before they “weigh out,” this extra space translates directly to shipping cost savings.

The shipping industry constantly innovates with these trailers. Some now feature side doors for easier access to front pallets, rolling floors for faster unloading, or temperature control systems for sensitive cargo.

The latest development involves aerodynamic side skirts and boat tails that can improve fuel efficiency by 5-15%.

Specialized Trucking Spaces

1. Refrigerated Trailers (“Reefers”)

These temperature-controlled trailers are essential for transporting perishable goods from farm to table and maintaining pharmaceutical supply chains.

Refrigerated trailers typically come in 48-foot and 53-foot lengths with interior dimensions slightly smaller than standard dry vans due to the insulation and refrigeration equipment. They maintain precise temperatures ranging from -20°F to 70°F depending on cargo requirements.

The technology behind modern reefers is impressive they can maintain multiple temperature zones within a single trailer and transmit real-time temperature data to ensure product safety.

These sophisticated systems add significant weight and cost; a reefer unit can add $30,000-50,000 to the price of a trailer.

An interesting development in the reefer market is the growing use of telematics that allow shippers to monitor not just temperature but also humidity, door openings, and even ethylene gas levels for transporting sensitive produce.

This technology helps reduce the estimated $35 billion in food spoilage that occurs annually during transport.

2. Flatbed Trailers

When cargo doesn’t fit neatly into a box, flatbeds become the solution handling everything from construction materials to industrial machinery.

Standard flatbeds measure 48 or 53 feet long with 8’6″ width but have no height restrictions other than legal road limits (typically 8’6″ to 13’6″ depending on state regulations). Their open design allows for loading from the top, sides, or rear.

These versatile platforms require specialized securing techniques drivers must master the art of using chains, straps, tarps, and edge protectors to ensure loads remain secure during transport.

The skill required for properly securing diverse loads explains why flatbed drivers often earn premium pay.

Despite their seemingly simple design, modern flatbeds incorporate sophisticated engineering, including sliding tandem axles that can be adjusted to distribute weight properly for different load configurations.

Some specialty flatbeds can even expand in width to accommodate oversized loads up to 12 feet wide.

3. Tanker Trucks

These specialized vehicles transport liquids and gases ranging from milk to gasoline to hazardous chemicals.

Tanker capacities typically range from 5,000 to 11,600 gallons depending on the product density and legal weight limits. Most tankers feature cylindrical designs that evenly distribute the weight of liquid cargo and prevent dangerous sloshing during transport.

The engineering behind these trucks includes baffles (internal walls) that reduce liquid movement and improve stability.

For food-grade tankers, specialized cleaning systems ensure zero contamination between loads a critical factor when the same tank might carry chocolate one day and cream the next.

Perhaps most impressive is the safety engineering in modern chemical tankers, which often feature multiple containment systems and pressure-relief devices.

This technology has dramatically reduced hazardous material incidents despite increasing chemical transport volumes.

Practical Applications of Trucking Space Knowledge

Choosing the Right Truck Size for Moving

Selecting an appropriately sized truck for your move can save hundreds of dollars while ensuring everything fits in a single trip. Here’s a quick reference guide:

- Studio/small one-bedroom: 10-12 foot truck (380-450 cubic feet)

- Large one-bedroom/small two-bedroom: 16 foot truck (800 cubic feet)

- Two to three-bedroom home: 20-24 foot truck (1,000-1,400 cubic feet)

- Four+ bedroom home: 26 foot truck (1,600 cubic feet) or larger commercial options

When estimating your needs, remember that furniture doesn’t pack perfectly irregularly shaped items create dead space. A good rule of thumb is to estimate your volume needs, then add 20% for inefficient packing.

See Also: DVD Case Sizes: The Standard and Beyond

Estimating Shipping Costs

Understanding trucking dimensions helps businesses optimize shipping costs through these approaches:

- Dimensional Weight Calculation: Many carriers charge based on either actual weight or dimensional weight (length × width × height ÷ a divisor), whichever is greater. Packaging efficiently to reduce dimensional weight can significantly lower shipping costs.

- Consolidation Opportunities: Knowing standard truck dimensions allows shippers to consolidate multiple orders into full truckload shipments, often saving 15-30% compared to LTL (Less Than Truckload) rates.

- Pallet Optimization: Standard trailers accommodate specific pallet arrangements. Designing packaging around these configurations improves space utilization and reduces costs.

Transportation managers who master these concepts often become their company’s unsung heroes, finding creative ways to reduce shipping costs while maintaining service levels.

Measuring Without Specialized Tools

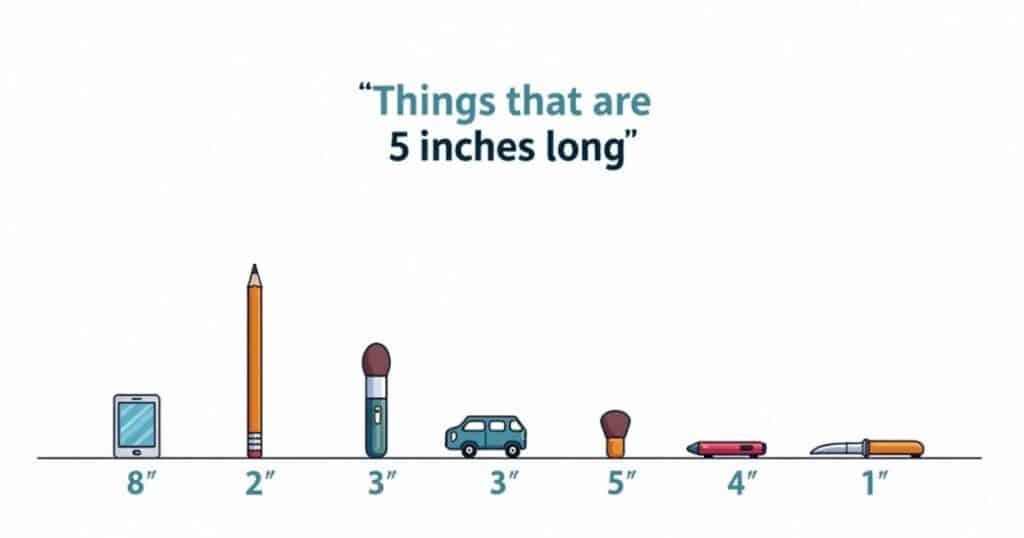

Need to estimate truck space requirements without a tape measure? Here are some practical techniques:

- Use your body: The average adult’s arm span is approximately their height. Measure your arm span once, then use it as a reference.

- Floor tiles: Many commercial buildings use standard 12-inch floor tiles. Count tiles to estimate length and width.

- Paper reference: A standard piece of paper is 8.5 × 11 inches perfect for estimating smaller dimensions.

- Smartphone apps: Many phones now include measuring tools that use the camera to estimate dimensions with surprising accuracy.

These improvised measuring techniques can help you quickly assess whether items will fit in available truck space without specialized tools.

Conclusion

Understanding trucking space dimensions has practical applications far beyond the shipping industry. Whether you’re:

- Planning a move and need to rent the right-sized truck

- Running a business that ships or receives goods

- Working in logistics and optimizing transportation networks

- Designing products with shipping efficiency in mind

…knowing these standard dimensions helps you make better decisions and potentially save significant money.

The next time you see trucks on the highway, you’ll appreciate the carefully designed ecosystem of standardized dimensions that enables efficient movement of goods across continents. From the precisely calculated interior dimensions of refrigerated trailers keeping your groceries fresh to the flatbeds transporting construction materials for new homes, these trucking spaces form the backbone of our modern economy.

Take a moment to look around your home or office nearly everything you see spent time in one of these trucking spaces on its journey to you. That’s the hidden but essential role these carefully designed spaces play in our daily lives.

What trucking space challenges have you encountered in your business or personal moves? Understanding these dimensions is the first step toward solving them efficiently.

Read more knowledgeable blogs on Measure Take.